List Of Materials Used In Building Construction

In this article, we will explain the list of materials used in building construction. Choosing the right materials for your project is vital. To be honest, we have covered a well researched list of materials used in building construction as follows:

- What are building material?

- 5 Main Families of building materials

- Metallic Building Material

- Organic Building Material

- Mineral Building Material

- Composite Building Material

- Characteristic And Different Types Of Building Material

What Are Building Materials in Construction?

List Of Building materials in construction

The range of materials used in the building construction industry (buildings and public works) is vast and is enriched every day, especially. New materials were created for different purposes, including.

5 Main Families List Of Building Materials In Construction

Besides having numerous list of building materials, they are five main families of building materials in construction. These are: metals, organics, minerals, composites and plastics.

1. Metallic Building Materials

Metals are ubiquitous in the world of construction today. These are the materials of choice for structure, and frames, including cladding, roofing, joinery, heating equipment and plumbing works.

Among their strong points are the high rigidity, leaving great freedom of creation. The high resistance support loads with less material and increased durability. Thanks to the resistance, at the same time, to bad weather, corrosion, UV and even to earthquakes.

Metal products also have the advantage of being able to be recycled in their entirety. Without altering the qualities of the metal, even after several recycling cycles. Unlike most non-metallic materials,

List Of Common Metals Used In Construction

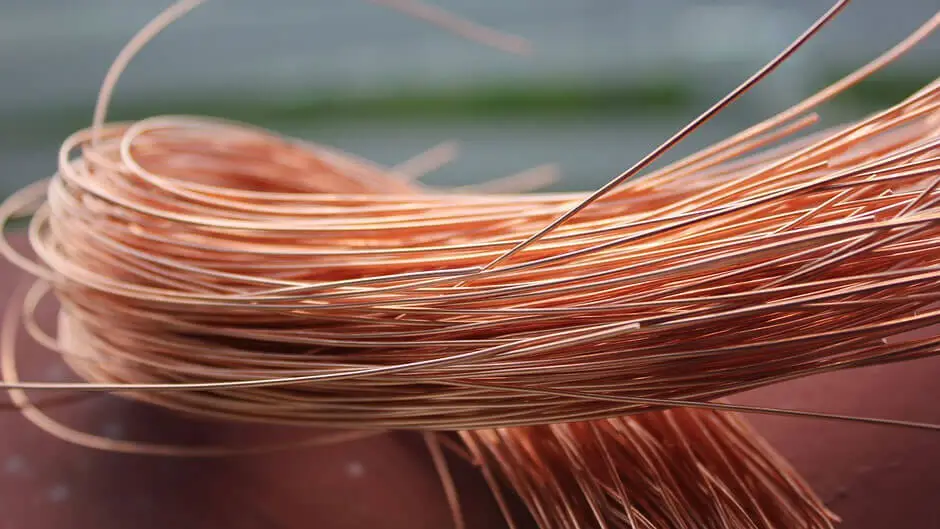

The most common metals used in construction listed as follows: steel (carbon, stainless), aluminium and copper.

Steel is particularly robust, and the frames made of this metal guarantee you a perfectly stable structure. Especially when it comes to carbon steel, generally used to manufacture beams, rigid pipes, profiles, etc.

Stainless steel, on the other hand, is efficient to corrosion and does not rust. Clarity can be used in many fields, in particular for the manufacture of sheet metal or plumbing elements. Such as taps or shower columns.

Light and ductile, aluminium is the modern material par excellence. And makes it possible to produce made-to-measure elements in many colours to meet all constraints. In addition, it is resistant to weather, and efficiently used in the design of windows, doors, bay windows, as well as other elements facing the outside. Call us now, at Last Builders, so that we can help you find a wide choice of aluminium joinery.

Contrary to aluminium, copper is one of the oldest building materials, which captivates with its timelessness and longevity. Being also resistant to corrosion, it is used for hot and cold water pipes, in heating systems, but also for various architectural elements: roofing, down spouts, gutters, etc.

2. Organic Building Materials

Organic building material mainly made up of carbon, hydrogen, nitrogen and oxygen atoms, organic materials can be of natural or synthetic origin, but it is preferable to treat the latter separately.

Types Of Organic Material In Building Construction

The Organic materials of natural origin were the first materials to be used by humans in construction projects. Nowadays, they are especially appreciated for their lightness, their elasticity and their capacity for thermal and electrical insulation.

They are also interesting from an environmental point of view because it is possible to produce them intelligently using renewable sources in order to limit the depletion of natural resources.

Natural organic materials are obtained from plants (plant origin) or animals (animal origin). Among the first to have been used, let us mention among others hemp, cotton or even cork which are used as insulation in the form of rolls, panels or in bulk, but also straw which can be used in the composition of some coatings, and of course wood.

This noble, aesthetic and easy-to-work material is in great demand in construction, from the creation of the framework to exterior or interior joinery.

Among the materials of animal origin , sheep’s wool and duck feathers are mainly used. They are good thermal insulators, respectful of the environment and human health.

3. Mineral Building Materials

Scientifically speaking, mineral materials are inorganic materials that have ionic and covalent bonds. These are rocks (building stone, gravel), ceramics (sandstone tiles, porcelain stoneware, terracotta) and glass.

These materials have been used since antiquity, and their nature has remained unchanged for several millennia. They are distinguished by their hardness and rigidity, as well as their mechanical and chemical resistance. They are ideal for heavy work.

Different Types Of Mineral Building Materials in Construction

Building stone is in particular one of the most used mineral materials in construction, even if today it is becoming increasingly rare in structural work because of its difficult implementation and its price.

Nevertheless, natural stone is still appreciated for its authentic side and its power to capture calories and accumulate them and then release them gently (inertia).

Brick is another traditional material widely used in masonry work. Made from clay and terracotta, the brick comes in four formats: solid, perforated, alveolar and hollow, each with its own particular properties.

Difference Between Hollow And Solid Brick

For example, solid brick is strong but heavy, while hollow brick is light but offers a poor level of thermal and sound insulation.

Porcelain stoneware tiles are part of the ceramic family. A mixture of clay and silica with the addition of other mineral materials, pressed and fired at a very high temperature, to then be covered or not with a layer of enamel, it is one of the most resistant in the world.

Uses Of Porcelain Stoneware Tiles

Main advantage of porcelain stoneware tiles are very widely used as a coating in modern construction or renovation because it represents a good compromise between technical performance and competitive price compared to other materials.

Do you need help? Call us for help in choosing the right material

4. Composite Building Materials

The composite material is an alloy of at least two immiscible materials:

First, it has properties that its components alone do not have. Second, it is made up of a framework, called a reinforcement, which provides mechanical strength, and a matrix which guarantees the cohesion of the structure and distributes the forces.

Classification Of Composite Material

Composites can be classified according to the nature of the matrix: it can be resin, organic or ceramic. The reinforcements can also be different: it is possible in particular to use glass fibres, carbon fibres and even plant fibres such as hemp and flax.

These include concrete and reinforced concrete, which shaped the face of the 20th century, plywood, used to build partitions, but also new materials, such as composite wood, made from recycled wood, crushed and mixed to a polymer resin.

Advantage of Composite Building Material

Its advantage: a preserved wood appearance, which is moreover with good resistance to heat, humidity and termites. There are also composite materials for roofing, such as fibre cement roofing sheets or recycled composite tiles. Lighter, more flexible and robust, these materials are the guarantee of a waterproof cover for many years.

Disadvantage Of Composite Building Material

One of the disadvantages of most composites are difficult to recycle due to the presence of thermosetting polymers.

Thus, to reduce the environmental impact of buildings, it is now possible to use biocomposites made with natural fibres from plants or cellulose, and a biodegradable matrix (e.g. PLA, poly lactic acid).

5. Plastic Building Materials

Definition: Plastic Building materials are polymers, usually mixed with additives, colourants and fillers.

Like natural organic materials, they contain carbon, but are man-made through chemical processes. The majority of them are obtained from petroleum, and they were developed in the 20th century to deal with the shortage of certain materials of natural origin.

Types Of Platic Materials

There are many types: thermoplastic polymers (ABS, PVC, etc.), elastomers (silicone, polyurethane, etc.), thermosetting polymers (epoxy, Bakelite, etc.), bioplastics (PLA, polyamide 11, etc.).

Uses Of Plastics In Construction Projects

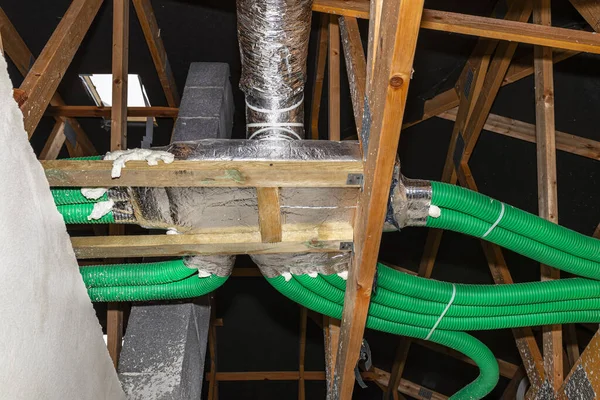

Most plastics have numerous useful properties in the field of construction.

- They are durable and resist corrosion, making them ideal for raceways and window and door frames.

- Light, malleable, easy to handle and transport, and reduce installation time.

- Easy to maintain and clean, so they are good floor and wall coverings, especially in environments that require impeccable hygiene.

- Plastics are inexpensive and at the same time good thermal, sound and electrical insulators. Thus, they make it possible to design affordable, high-quality housing with low energy consumption.

- Used for the exterior (as coating, insulation, to channel rainwater, etc.), for the interior (coatings, joinery.

Advantages Of Plastic Materials

Fortunately, plastic waste is becoming a source for construction. Through mechanical or chemical recycling, opaque PET waste can, for example, be transformed into insulation foam.

End-of-life windows, doors, cables and pipes can be mechanically transformed into pellets and reused for the same applications.

Recycled PVC mixed with sawdust can be used to make deck boards. In the end, by using plastic materials for construction, it is possible to fight against pollution.

Disadvantages Of Plastics In Construction

The problem with plastic material faced in most construction projects is that very little is recycled, with many going to landfill or lost to nature.

Characteristics And Different Types Of Building Materials

In a construction, each material plays a specific role.

Wall materials, for example, support the weight of the roof and at the same time withstand the constant onslaught of the elements.

The materials of the openings must allow light to pass through, but they must not let through water, cold or heat.

Filling of the walls, in addition to their supporting and protective function, must make it possible to maintain a comfortable temperature inside.

That is why each element plays its role to perfection, it is important to choose the building materials according to their fields of use and their main characteristics.

Strongest Building Materials

Every home builder wants to build a solid house. But we must also not forget that the climate and its constraints may be different from one region to another, and the requirements concerning the resistance will not be the same either.

Thus, in a region subject to severe weather, it will be necessary to favour reinforced concrete blocks. In an earthquake zone, lighter and more elastic materials, such as wood or steel, will be preferable.

Conversely, wood will not be sufficiently resistant in a humid environment, and cinder blocks and concrete blocks should be preferred, with anti-capillary insulation for the facades.

As for the brick, it has excellent resistance to strong temperature variations, which makes it a suitable product for regions subject to significant heat peaks.

The Most Insulating Building Materials In Construction

When it comes to Construction projects, most conventional building materials must be associated with insulation in order to guarantee a good level of thermal comfort to the occupants of the dwelling while not wasting energy by overheating.

Since heat loss is greater in the attic and the roof, it is these walls that should be insulated as a priority.

Two Fundamental Roles Of Insulators

A thermal insulator is a material that has two fundamental roles: it prevents the heat from entering in summer and, on the other hand, it preserves the dwelling from the cold in winter.

For this, it must absorb very little heat: its surface temperature can indeed rise very quickly, but only change very slowly inside. Everything depends on the thermal conductivity and the thickness of the insulation.

Best Insulation Material

Among the best insulators are synthetic (polyurethane foam), natural (sheep’s wool, cellulose wadding) and mineral (rock wool, glass wool) insulation.

Synthetic insulators are the most frequently used because they have a good cost-effectiveness ratio.

But they are less efficient in terms of sound insulation and can be harmful to health while having a certain impact on the environment. This is also the case for mineral wools, which can also settle, which reduces their lifespan.

Natural fibre insulation is biodegradable and has a low impact on the environment, but it can be destroyed by animals that eat it or by fungi if it gets wet. To be chosen according to the specifications!

Also note that, as the insulation sector is expanding, new insulations appear on the market regularly. These include so-called “new generation” insulation, such as single-wall bricks, insulating formwork, insulating paint, etc.

To find the insulation that best suits your needs, do not hesitate to call Last Days Builders

Most Malleable Building Materials

Malleability is the ability of a material to deform hot or cold without breaking, and to retain its new shape. It can thus be flattened, bent, curved. Most metals and their alloys are malleable and ductile, that is, they can stretch without breaking, and are often selected for the manufacture of wires and cables.

The malleability makes it possible to obtain various shapes and aesthetic finishes. Steel and aluminium radiators can thus take on the most designer forms while the more malleable metals, such as zinc, can be used to produce roofing and rainwater drainage elements, cladding and decorations of facades.

Even for structural work, it is unwise to focus only on the hardest metals (note that the hardness of steels is determined by their carbon content), because the harder a metal is, the harder it is, even impossible, to solder.

Plastics are also very malleable: some can be heated, then shaped in the moulds and then reheated and reshaped; others may only be heated and shaped once. They are mainly used for the manufacture of pipes and tanks, as well as other elements with complex shapes.

What Are Conductive Materials?

Conductive materials are opposed to an insulator, a conductor is a material allowing energy exchanges between two systems. There are thermal, electrical and optical conductors.

In the field of construction, it is above all the thermal and electrical conductivity that interests us, and it is still the metals that are found at the top of the table.

Copper is in fact the most used to make electrical wires and cables, while steel and aluminium are used more in heat distribution and evacuation systems (cooling).

Which materials are recyclable and the most friendly to the environment?

Today, humanity has understood that natural resources are not inexhaustible. This is why the modern house should not only focus on comfort, but also on its overall ecological impact. In this context, the use of sustainable products, non-polluting, recyclable materials takes on its full meaning.

Examples Of Preferred Materials:

These are some examples of preferred materials

- Wood, natural and renewable, with good thermal performance.

- Hemp concrete, made from hemp debris and a lime-based binder with very interesting characteristics (thermal and acoustic insulation, elasticity).

- The single-wall brick, which preserves heat in summer and allows energy savings in winter, to be used without insulation.

Things To Consider When Using Organic Materials

On the insulation side, it is preferable to use organic materials (such as straw or cellulose wadding), which are less toxic than mineral wool. As for finishes, mineral paints (lime, clay) and natural coatings will be less harmful than, for example, vinyl floors and glycerol paint.

It is also necessary to wonder about the quantity of energy necessary throughout the life cycle of the building material, that is to say for its manufacture, its transport, its storage, its distribution, its use, its maintenance and finally, it’s recycling or disposal. This is what is called “gray energy”.

Metals and synthetic materials consume a lot of embodied energy, as do products that come from afar. The least processed products, the least heavy and consumed as close as possible to their place of production, consume little embodied energy. Solid wood will therefore be the big winner, while cinder block and brick will be the most energy-intensive.

Building a house today while having the lowest possible environmental impact is not an easy task between the need on the one hand to take into account energy and environmental issues, and on the other, not to sacrifice comfort. Traditional construction materials, known for millennia, but also the most efficient modern materials, are there to make your job easier. Just choose them carefully!

Trust your building supply store to help you

All the advisors at Last Days Builders will be happy to support you throughout your various projects. Don’t hesitate to contact them and ask for their advice.

Let Last Days Builders visit you and give you a quotation For that! You even have the option of making an appointment for personalized support! Call now

Leave a Reply